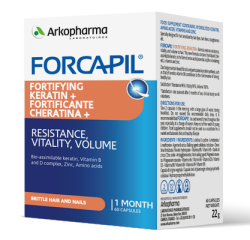

Discover our best sellers

Forcapil® Fortifying Keratin+

Arkorelax Sommeil Kids BIO

Cys-Control® Fort with microbiotic

Our mission

At Arkopharma, we want to make Natural Medicine the Medicine of the Future. Efficient, more respectful of the body and its balance, with better assimilation, and less prone to generating intolerances.

Our goal is for it to become the first choice for consumers and healthcare professionals when it comes to preventing and relieving everyday ailments.

At Arkopharma we believe that Nature's extraordinary intelligence can be enhanced through our modern pharmacological science. For 40 years, our pharmaceutical laboratory and our researchers have been working hard to convert this intelligence into natural remedies for health problems, combining science, innovation and guaranteed safety, always with a deep respect for the environment.

We want to offer deeper, longer-lasting daily well-being – giving everyone the opportunity to enjoy a fuller life.